Anthony Snell, President of the International Blackcurrant Association since June 2016, opens the doors of his farm for us.

Anthony Snell, President of the International Blackcurrant Association since June 2016, opens the doors of his farm for us.

Professionalism, perfection and experience in Herefordshire, UK.

Visited in March 2017

The first impression of a visitor at Windmill Hill in Western England will be “WOW”. And it will also be the last impression, after having a deep look into Anthony Snell’s business. As it proudly shows on banners, Windmill Hill is where you will get the “berry” best from Herefordshire.

The first impression of a visitor at Windmill Hill in Western England will be “WOW”. And it will also be the last impression, after having a deep look into Anthony Snell’s business. As it proudly shows on banners, Windmill Hill is where you will get the “berry” best from Herefordshire.

For many years, Anthony Snell and his wife Christine have been running the family business in beautiful hilly and green Herefordshire. Berries are their speciality, and among these: blackcurrants. Anthony has a field manager for the strictly agronomic part of his business, but keeps an eye on everything – and knows everything about blackcurrants.

“Blackcurrant production must meet the demand of the market” says Anthony Snell

Anthony’s blackcurrant farm is of average size – and average in the UK means 70 – 100 hectares. He is one of the 8 blackcurrant growers in Herefordshire, who are part of the British Blackcurrant Foundation. The other members of the foundation, in total around 40 blackcurrant farmers in the whole United Kingdom, grow their blackcurrants for the needs of Ribena. This represents 90% of the crop in the country. Ribena, a blackcurrant based British soft drink brand owned today by Suntory, contracts the blackcurrant growing for their needs with British growers.

Anthony’s blackcurrant farm is of average size – and average in the UK means 70 – 100 hectares. He is one of the 8 blackcurrant growers in Herefordshire, who are part of the British Blackcurrant Foundation. The other members of the foundation, in total around 40 blackcurrant farmers in the whole United Kingdom, grow their blackcurrants for the needs of Ribena. This represents 90% of the crop in the country. Ribena, a blackcurrant based British soft drink brand owned today by Suntory, contracts the blackcurrant growing for their needs with British growers.

The “Ribena-system”

The contract between Ribena and the British Blackcurrant Foundation is the basis for good relationships between growers and processors. Here, the production corresponds to the needs, and everybody is happy: a certain price level is fixed approximately within a contract that lasts for seven years. Prices are, of course, adjusted after the harvest, according to the quality of the currants. But it ensures the growers to sell their currants, and it ensures Ribena good growing conditions for “their” currants.

Anthony buys blackcurrant cuttings of “Ribena varieties” from a certified producer. And he only plants a certain

amount of blackcurrants, paying royalties for the amount of cuttings he plants. “Last year, I had to remove blackcurrants from some areas (variety Ben Hope), because I produced too much”, explains Anthony. Five times a year, Harriet Roberts, agronomic adviser from LRS (Lucozade Ribena Suntory), visits every farmer. Together with a newsletter that she sends twice a month, this part of the contract. It helps the growers with professional agronomic advice.

Organic blackcurrants from Windmill Hill

Where there is no place for “Ribena”-blackcurrants, Anthony grows organic. Blackcurrants of variety Ben Tirran represent 20% of the total area. Here, hand weeding and hand fertilizing is taking over from spraying and work with huge machines for the first 2 years of the plantation. The strict respect of organic growing methods will guarantee a good yield – which is half of the conventional yield. “In conventional growing, 7 tonnes per hectare is a good average”, says Anthony.

Where there is no place for “Ribena”-blackcurrants, Anthony grows organic. Blackcurrants of variety Ben Tirran represent 20% of the total area. Here, hand weeding and hand fertilizing is taking over from spraying and work with huge machines for the first 2 years of the plantation. The strict respect of organic growing methods will guarantee a good yield – which is half of the conventional yield. “In conventional growing, 7 tonnes per hectare is a good average”, says Anthony.

Windmill Hill sells its organic blackcurrants to companies who make organic yogurts or cordial, for example. But this is not all: Anthony has his own storage and packing facilities for IQF berries – and he sells them online.

The “berry” best from Herefordshire

Apart from blackcurrants, Windmill Hill produces raspberries (40ha), a thousand tonnes of strawberries a year, together with some blueberries, chuckleberries and blackberries. During the harvesting season, around 300 seasonal staff join the permanent workers. They come from Bulgaria, Romania or Poland, and Anthony and Christine are very concerned by their well-being. They provide accommodation in mobile homes on the farm for some of them, and they have their football and tennis facilities for spare time activities.

Apart from blackcurrants, Windmill Hill produces raspberries (40ha), a thousand tonnes of strawberries a year, together with some blueberries, chuckleberries and blackberries. During the harvesting season, around 300 seasonal staff join the permanent workers. They come from Bulgaria, Romania or Poland, and Anthony and Christine are very concerned by their well-being. They provide accommodation in mobile homes on the farm for some of them, and they have their football and tennis facilities for spare time activities.

During the tour of the farm, Anthony gives some details about his blackcurrant farming. “Ben Alder is the variety which has the best yield here with 4t/acre (10t/hectare). It is a very consistent variety”, explains Anthony. “We have an average of 600mm of rain per year. When we plant cuttings, we keep them under polythene for the first 3 years. This is part of the recommendation of Ribena: it keeps weeds away and moisture in. We keep our plantations for 10 to 12 years, in general.”

During the tour of the farm, Anthony gives some details about his blackcurrant farming. “Ben Alder is the variety which has the best yield here with 4t/acre (10t/hectare). It is a very consistent variety”, explains Anthony. “We have an average of 600mm of rain per year. When we plant cuttings, we keep them under polythene for the first 3 years. This is part of the recommendation of Ribena: it keeps weeds away and moisture in. We keep our plantations for 10 to 12 years, in general.”

Furthermore, hedges delimit the blackcurrant fields. It is part of the environmental commitment from the Ribena growers. Hedges, flowers and wildlife are present everywhere on the farms.

Furthermore, hedges delimit the blackcurrant fields. It is part of the environmental commitment from the Ribena growers. Hedges, flowers and wildlife are present everywhere on the farms.

At the end of the tour, Anthony shows us his machinery. Not far from harvesting machines, tractors, sprayers and all the other farming material, some cows have their paddock. “This is Christine’s hobby”, smiles Anthony. Because even though fruits have become an expanding activity in the Western Midlands, Hereford cattle is probably still its most famous export.

At the end of the tour, Anthony shows us his machinery. Not far from harvesting machines, tractors, sprayers and all the other farming material, some cows have their paddock. “This is Christine’s hobby”, smiles Anthony. Because even though fruits have become an expanding activity in the Western Midlands, Hereford cattle is probably still its most famous export.

Heiko Danner is a wine growing engineer. He grows wine grapes and has made his own wines for 14 years. He had taken over his father’s farm, where wine-growing had always been part of the farming business. His ancestors had distilling rights and had always produced fruit spirits. At first, Heiko simply continued the tradition. But then, he turned towards blackcurrants.

Heiko Danner is a wine growing engineer. He grows wine grapes and has made his own wines for 14 years. He had taken over his father’s farm, where wine-growing had always been part of the farming business. His ancestors had distilling rights and had always produced fruit spirits. At first, Heiko simply continued the tradition. But then, he turned towards blackcurrants. In Stockheim, close to Heilbronn in Southern Germany, the fields are rather small and not very good for growing wheat or the like. But the soil is good for grapes – and why not blackcurrants? This is what Heiko thought after some years of wine growing. When it comes to blackcurrant growing, many agricultural aspects are quite similar to wine growing. Soil, plant protection, machines, climate – but the harvest is at another moment of the year. Diversification from wine growing towards blackcurrant growing is therefore a natural development.

In Stockheim, close to Heilbronn in Southern Germany, the fields are rather small and not very good for growing wheat or the like. But the soil is good for grapes – and why not blackcurrants? This is what Heiko thought after some years of wine growing. When it comes to blackcurrant growing, many agricultural aspects are quite similar to wine growing. Soil, plant protection, machines, climate – but the harvest is at another moment of the year. Diversification from wine growing towards blackcurrant growing is therefore a natural development.

The duration of a blackcurrant field on the Tavendale farm is of roughly 15 years, some even 19. Whereas at my home in Germany, we harvest for 12 years. During this long lifetime, regular pruning is necessary. What also struck me was the height of the currant shrub. They grow up to 2.5 meters and their lower branches are therefore very thick.Furthermore, what also differs from

The duration of a blackcurrant field on the Tavendale farm is of roughly 15 years, some even 19. Whereas at my home in Germany, we harvest for 12 years. During this long lifetime, regular pruning is necessary. What also struck me was the height of the currant shrub. They grow up to 2.5 meters and their lower branches are therefore very thick.Furthermore, what also differs from

The harvesting process also differs significantly from home. My stay here in New Zealand is a very rich experience also for this reason: I have learned many new points of view and processing steps. As an example, we harvest the currants with three harvesters:

The harvesting process also differs significantly from home. My stay here in New Zealand is a very rich experience also for this reason: I have learned many new points of view and processing steps. As an example, we harvest the currants with three harvesters:

He generally rents hives for a better pollination. Rapeseed and blackcurrants grow not far from each other, they both attract bees and bumblebees.When he plants new fields of blackcurrants, Guillaume doesn’t use plastic any more. “I used to plant them under plastic foil before, but I have stopped this. There will be weeds anyhow, and removing them is more complicated with plastic around”, explains Guillaume.

He generally rents hives for a better pollination. Rapeseed and blackcurrants grow not far from each other, they both attract bees and bumblebees.When he plants new fields of blackcurrants, Guillaume doesn’t use plastic any more. “I used to plant them under plastic foil before, but I have stopped this. There will be weeds anyhow, and removing them is more complicated with plastic around”, explains Guillaume.

Growing blackcurrants is important for Guillaume, and he is well aware of their potential for our health. Nevertheless, he is not very optimistic for the future. “Not enough people buy blackcurrants – or rather blackcurrant products – because we do not yet sell them as IQF in France. I don’t know for how long I will continue, but I hope it will turn to the better.”

Growing blackcurrants is important for Guillaume, and he is well aware of their potential for our health. Nevertheless, he is not very optimistic for the future. “Not enough people buy blackcurrants – or rather blackcurrant products – because we do not yet sell them as IQF in France. I don’t know for how long I will continue, but I hope it will turn to the better.”

In April this year, I have paid a visit to one of the German blackcurrant growers, Michael Bullinger. All those who have attended our conferences have certainly already met him. He is always present (although discreet), and he was also part of the organizing team of the German conference in Waldenburg in 2013. His farm, “Obsthof Bullinger”, is in Kupfer, not far from Waldenburg. And it is a pure family business: no employees – only passion for blackcurrants.

In April this year, I have paid a visit to one of the German blackcurrant growers, Michael Bullinger. All those who have attended our conferences have certainly already met him. He is always present (although discreet), and he was also part of the organizing team of the German conference in Waldenburg in 2013. His farm, “Obsthof Bullinger”, is in Kupfer, not far from Waldenburg. And it is a pure family business: no employees – only passion for blackcurrants.

A blackcurrant beer named “SALAMANDER Blackcurrant Berliner Weisse beer”. The inauguration took place in Poland in mid-July and is the outcome of a collaboration between the Polish Blackcurrant Growers Association (KSPCP) and Browar Stu Mostów brewery.

A blackcurrant beer named “SALAMANDER Blackcurrant Berliner Weisse beer”. The inauguration took place in Poland in mid-July and is the outcome of a collaboration between the Polish Blackcurrant Growers Association (KSPCP) and Browar Stu Mostów brewery. The product launch ceremony was held simultaneously in Wrocław and Lublin. Wrocław is the seat of

The product launch ceremony was held simultaneously in Wrocław and Lublin. Wrocław is the seat of  The blackcurrant beer was launched under the Salamander brand. Salamander is an old beer, which emerged at the beginning of the 19th century in Wrocław. It shows the power of meeting over a beer, friendship and respect. Up to the present day, during feasts held by German student corporations, they still cultivate and practice this custom. Product-wise, it is of course a new-wave beer.

The blackcurrant beer was launched under the Salamander brand. Salamander is an old beer, which emerged at the beginning of the 19th century in Wrocław. It shows the power of meeting over a beer, friendship and respect. Up to the present day, during feasts held by German student corporations, they still cultivate and practice this custom. Product-wise, it is of course a new-wave beer. “In addition to the colour, the flavour and the aroma, blackcurrant also adds extra acidity. Beers of this kind are gaining popularity, with the Berliner Weisse style going through a real revival. This is a trend we should take advantage of” claims Mateusz Gulej, Chief Brewer of the Browar Stu Mostów brewery.The blackcurrant beer is a very interesting beer. It has a very low gravity, and only bright malts – Pilsner and wheat – have been used. That is what makes the beer so light. The low, almost impalpable bitterness is due to the use of the noble Tettnanger hops. The brewers add the blackcurrants at the late stage of fermentation and aging. Blackcurrants gave the beer its characteristic flavour and aroma and emphasized its acidic profile even more.The Salamander blackcurrant beer is available at the best multitap pubs and beer stores across Poland and in the Czech Republic, Germany, Austria, Denmark, the Netherlands and Spain.

“In addition to the colour, the flavour and the aroma, blackcurrant also adds extra acidity. Beers of this kind are gaining popularity, with the Berliner Weisse style going through a real revival. This is a trend we should take advantage of” claims Mateusz Gulej, Chief Brewer of the Browar Stu Mostów brewery.The blackcurrant beer is a very interesting beer. It has a very low gravity, and only bright malts – Pilsner and wheat – have been used. That is what makes the beer so light. The low, almost impalpable bitterness is due to the use of the noble Tettnanger hops. The brewers add the blackcurrants at the late stage of fermentation and aging. Blackcurrants gave the beer its characteristic flavour and aroma and emphasized its acidic profile even more.The Salamander blackcurrant beer is available at the best multitap pubs and beer stores across Poland and in the Czech Republic, Germany, Austria, Denmark, the Netherlands and Spain. The IBA Exec members and Dr Dorota Jarret from the

The IBA Exec members and Dr Dorota Jarret from the

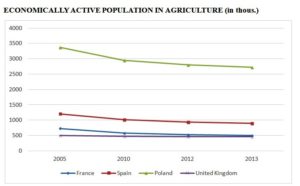

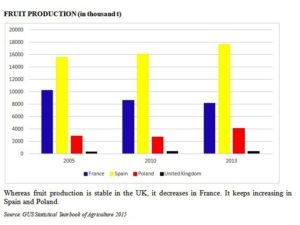

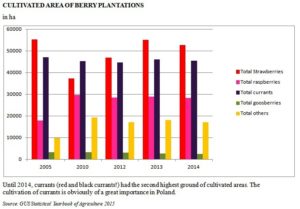

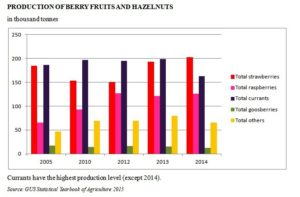

Keeping these figures in mind, the producers who are members of the

Keeping these figures in mind, the producers who are members of the

Anthony Snell, President of the International Blackcurrant Association since June 2016, opens the doors of his farm for us.

Anthony Snell, President of the International Blackcurrant Association since June 2016, opens the doors of his farm for us.

The first impression of a visitor at Windmill Hill in Western England will be “WOW”. And it will also be the last impression, after having a deep look into Anthony Snell’s business. As it proudly shows on banners, Windmill Hill is where you will get the “berry” best from Herefordshire.

The first impression of a visitor at Windmill Hill in Western England will be “WOW”. And it will also be the last impression, after having a deep look into Anthony Snell’s business. As it proudly shows on banners, Windmill Hill is where you will get the “berry” best from Herefordshire. Anthony’s blackcurrant farm is of average size – and average in the UK means 70 – 100 hectares. He is one of the 8 blackcurrant growers in Herefordshire, who are part of the

Anthony’s blackcurrant farm is of average size – and average in the UK means 70 – 100 hectares. He is one of the 8 blackcurrant growers in Herefordshire, who are part of the

Where there is no place for “Ribena”-blackcurrants, Anthony grows organic. Blackcurrants of variety

Where there is no place for “Ribena”-blackcurrants, Anthony grows organic. Blackcurrants of variety

Apart from blackcurrants, Windmill Hill produces raspberries (40ha), a thousand tonnes of strawberries a year, together with some blueberries, chuckleberries and blackberries. During the harvesting season, around 300 seasonal staff join the permanent workers. They come from Bulgaria, Romania or Poland, and Anthony and Christine are very concerned by their well-being. They provide accommodation in mobile homes on the farm for some of them, and they have their football and tennis facilities for spare time activities.

Apart from blackcurrants, Windmill Hill produces raspberries (40ha), a thousand tonnes of strawberries a year, together with some blueberries, chuckleberries and blackberries. During the harvesting season, around 300 seasonal staff join the permanent workers. They come from Bulgaria, Romania or Poland, and Anthony and Christine are very concerned by their well-being. They provide accommodation in mobile homes on the farm for some of them, and they have their football and tennis facilities for spare time activities.

During the tour of the farm, Anthony gives some details about his blackcurrant farming. “Ben Alder is the variety which has the best yield here with 4t/acre (10t/hectare). It is a very consistent variety”, explains Anthony. “We have an average of 600mm of rain per year. When we plant cuttings, we keep them under polythene for the first 3 years. This is part of the recommendation of Ribena: it keeps weeds away and moisture in. We keep our plantations for 10 to 12 years, in general.”

During the tour of the farm, Anthony gives some details about his blackcurrant farming. “Ben Alder is the variety which has the best yield here with 4t/acre (10t/hectare). It is a very consistent variety”, explains Anthony. “We have an average of 600mm of rain per year. When we plant cuttings, we keep them under polythene for the first 3 years. This is part of the recommendation of Ribena: it keeps weeds away and moisture in. We keep our plantations for 10 to 12 years, in general.” Furthermore, hedges delimit the blackcurrant fields. It is part of the environmental commitment from the Ribena growers. Hedges, flowers and wildlife are present everywhere on the farms.

Furthermore, hedges delimit the blackcurrant fields. It is part of the environmental commitment from the Ribena growers. Hedges, flowers and wildlife are present everywhere on the farms. At the end of the tour, Anthony shows us his machinery. Not far from harvesting machines, tractors, sprayers and all the other farming material, some cows have their paddock. “This is Christine’s hobby”, smiles Anthony. Because even though fruits have become an expanding activity in the Western Midlands, Hereford cattle is probably still its most famous export.

At the end of the tour, Anthony shows us his machinery. Not far from harvesting machines, tractors, sprayers and all the other farming material, some cows have their paddock. “This is Christine’s hobby”, smiles Anthony. Because even though fruits have become an expanding activity in the Western Midlands, Hereford cattle is probably still its most famous export. The International Blackcurrant Association has started to collect data from blackcurrant breeding centers. A collection of almost 70 commercially available blackcurrant varieties is

The International Blackcurrant Association has started to collect data from blackcurrant breeding centers. A collection of almost 70 commercially available blackcurrant varieties is