Best of cassis smoothie contest 2017

There was a hustle and bustle all around the IBA booth during the Smoothie Contest 2017 in Nuits-Saint-Georges. Over 1000 visitors came to taste and evaluate the 8 different smoothies, prepared by food bloggers, smoothie lovers and chefs.

When the Tour de France 2017 arrived in Nuits-Saint-Georges, 8 professional or amateur cooks competed their own way. With the help of blenders, they prepared their own version of a blackcurrant smoothie. The spectators who were waiting for the cycle competitors to arrive were the judges. They could taste the 8 different smoothies and elect their favorite beverage. At the end of a busy day, the participants of the first “Best of Cassis” – contest prepared one last big glass of smoothie. But this time, it was for a panel of 3 professionals: a chef, a blackcurrant professional and the manager of a gourmet magazine. A smoothie contest like you have never seen it before!

Get an idea of the atmosphere of a lovely day in this picture review:

The booth in Nuits-Saint-Georges – and great public!

Evaluation by the professional panel at the Cassissium

Cocktail class for the participants and gifts for everyone

participants

Nothing could have happened without them: Many thanks to all those who helped us to make this smoothie contest a great success!!!

As announced previously, the New Product Development Unit of the IBA, a core group of blackcurrant product professionals with the support of Austria Juice, launched this first “Best of Cassis” contest.

Of course, a contest needs competitors. We had limited the number of participants to 8. And found 8 highly motivated smoothie-makers: Karine, Baptiste, Nicole, Léa, Elaine, Chern, Diane and Hubert.

They made their smoothies with 35 liters of blackcurrant concentrate from Austria Juice.

Almost 400 kg of fruits, vegetables and dairy products came from the main sponsor of the Tour de France: Carrefour.

SEB, one of the leading producers of small domestic equipment, offered 8 brand new high speed blenders to the participants.

The Cassissium, the blackcurrant museum by Védrenne in Nuits-Saint-Georges, helped with the location, water, ice cubes, tables, helpers and many more.Finally, help, prizes and gifts came from many: Le Richebourg, Spa Hôtel La Cueillette, Château de Gilly, Le Cassissium, Vinésime, Castel de Très Girard, Nectars de Bourgogne, Mulot&Petitjean, Veuve Ambal, Anis de Flavigny, Moutarderie Fallot, Nuits-Saint-Georges, Arts & Gastronomie

Find all the recipes here!

The “Cheese cake blackcurrant smoothie” by chef Chern has won the professional panel’s prize. Try it yourself!

If you want to read more about the contest or keep in touch with us for the next one, follow us on our “Best of Cassis” page:

In April this year, I have paid a visit to one of the German blackcurrant growers, Michael Bullinger. All those who have attended our conferences have certainly already met him. He is always present (although discreet), and he was also part of the organizing team of the German conference in Waldenburg in 2013. His farm, “Obsthof Bullinger”, is in Kupfer, not far from Waldenburg. And it is a pure family business: no employees – only passion for blackcurrants.

In April this year, I have paid a visit to one of the German blackcurrant growers, Michael Bullinger. All those who have attended our conferences have certainly already met him. He is always present (although discreet), and he was also part of the organizing team of the German conference in Waldenburg in 2013. His farm, “Obsthof Bullinger”, is in Kupfer, not far from Waldenburg. And it is a pure family business: no employees – only passion for blackcurrants.

A blackcurrant beer named “SALAMANDER Blackcurrant Berliner Weisse beer”. The inauguration took place in Poland in mid-July and is the outcome of a collaboration between the Polish Blackcurrant Growers Association (KSPCP) and Browar Stu Mostów brewery.

A blackcurrant beer named “SALAMANDER Blackcurrant Berliner Weisse beer”. The inauguration took place in Poland in mid-July and is the outcome of a collaboration between the Polish Blackcurrant Growers Association (KSPCP) and Browar Stu Mostów brewery. The product launch ceremony was held simultaneously in Wrocław and Lublin. Wrocław is the seat of

The product launch ceremony was held simultaneously in Wrocław and Lublin. Wrocław is the seat of  The blackcurrant beer was launched under the Salamander brand. Salamander is an old beer, which emerged at the beginning of the 19th century in Wrocław. It shows the power of meeting over a beer, friendship and respect. Up to the present day, during feasts held by German student corporations, they still cultivate and practice this custom. Product-wise, it is of course a new-wave beer.

The blackcurrant beer was launched under the Salamander brand. Salamander is an old beer, which emerged at the beginning of the 19th century in Wrocław. It shows the power of meeting over a beer, friendship and respect. Up to the present day, during feasts held by German student corporations, they still cultivate and practice this custom. Product-wise, it is of course a new-wave beer. “In addition to the colour, the flavour and the aroma, blackcurrant also adds extra acidity. Beers of this kind are gaining popularity, with the Berliner Weisse style going through a real revival. This is a trend we should take advantage of” claims Mateusz Gulej, Chief Brewer of the Browar Stu Mostów brewery.The blackcurrant beer is a very interesting beer. It has a very low gravity, and only bright malts – Pilsner and wheat – have been used. That is what makes the beer so light. The low, almost impalpable bitterness is due to the use of the noble Tettnanger hops. The brewers add the blackcurrants at the late stage of fermentation and aging. Blackcurrants gave the beer its characteristic flavour and aroma and emphasized its acidic profile even more.The Salamander blackcurrant beer is available at the best multitap pubs and beer stores across Poland and in the Czech Republic, Germany, Austria, Denmark, the Netherlands and Spain.

“In addition to the colour, the flavour and the aroma, blackcurrant also adds extra acidity. Beers of this kind are gaining popularity, with the Berliner Weisse style going through a real revival. This is a trend we should take advantage of” claims Mateusz Gulej, Chief Brewer of the Browar Stu Mostów brewery.The blackcurrant beer is a very interesting beer. It has a very low gravity, and only bright malts – Pilsner and wheat – have been used. That is what makes the beer so light. The low, almost impalpable bitterness is due to the use of the noble Tettnanger hops. The brewers add the blackcurrants at the late stage of fermentation and aging. Blackcurrants gave the beer its characteristic flavour and aroma and emphasized its acidic profile even more.The Salamander blackcurrant beer is available at the best multitap pubs and beer stores across Poland and in the Czech Republic, Germany, Austria, Denmark, the Netherlands and Spain. The IBA Exec members and Dr Dorota Jarret from the

The IBA Exec members and Dr Dorota Jarret from the

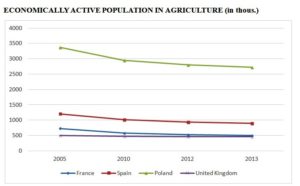

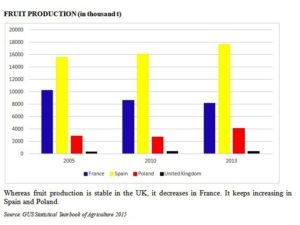

Keeping these figures in mind, the producers who are members of the

Keeping these figures in mind, the producers who are members of the