Austria Juice’s definition of sustainability

Sustainability – a word which is in everybody’s mouth nowadays. In fact, in the past 25 years, we have all become aware that our way of producing, living and consuming was irrespective of the natural ressources and lacked of humanity and fairness in many ways.

New ways of going forward to the future have been developed since. It applies to any field – blackcurrants are not an exception. What does sustainability mean for big players in this industry, like the juice processors?

We have asked Julia Wurzer from the marketing department of AUSTRIA JUICE, one of the biggest processors in Europe.

What does sustainability mean for Austria Juice?

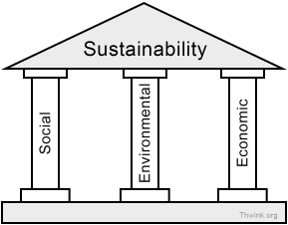

“Austria Juice interprets sustainability as a harmonious balance of economic, environmental and social responsibility. Based on this, we formulate three principles that sum up our concept of sustainability:

1. utilize almost 100% of raw materials and employ low-emission technologies to protect the environment

2. respect all stakeholders and the communities where Austria Juice operates

3. engage in long-term partnerships with suppliers and customers”

Sustainable sourcing of raw material

It sounds like there is something very interesting for our growers among these principles: long-term partnerships with suppliers. What does this precisely consist in?Julia Wurzer: “We source and process fruits where they grow and thus reduce long transport ways and supply chains. A good example for this is our Integrated Plantation Project, which we conducted for apples, sour cherries and elderberries.”

Integrated Plantation Project

“In fact, we had noticed that the availability of apples in Eastern-Hungary kept decreasing since the 1990ies. The climatic conditions for apple cultivation were perfect in this region, though. But the farmers had less productivity than earlier: the apple varieties in their orchards were old and not suitable any more. On the other side, Austria Juice wanted to continue using Hungarian raw material, having already three factories in this area. We wanted to build up a sustainable and state-of-art apple growing system”, explains Julia Wurzer.

IPP in a few words

Together with a breeding institute and universities, the cooperation model with Hungarian farmers resulted in the plantation of new, prefectly suiting varieties for the region. They have less environmental impact, as they are resistent against the main deseases. This, of course, reduces the need for plant protection products – and therefore results in lower production costs. In total, 900 farmers participated in this programme. They planted a total of 3700 hectares of new orchards between 2000 and 2015. For this, Austria Juice supported them with a 15 years contract and several advisors to support the farmers with their everyday challenges.

Together with a breeding institute and universities, the cooperation model with Hungarian farmers resulted in the plantation of new, prefectly suiting varieties for the region. They have less environmental impact, as they are resistent against the main deseases. This, of course, reduces the need for plant protection products – and therefore results in lower production costs. In total, 900 farmers participated in this programme. They planted a total of 3700 hectares of new orchards between 2000 and 2015. For this, Austria Juice supported them with a 15 years contract and several advisors to support the farmers with their everyday challenges. “The efficiency of apple production is higher now and we have full traceability of our raw material. We now aim to achieve the transformation into organic production in the framework of this project”, Julia Wurzer continues.

“The efficiency of apple production is higher now and we have full traceability of our raw material. We now aim to achieve the transformation into organic production in the framework of this project”, Julia Wurzer continues.

Sustainability “made by Austria Juice” for blackcurrants

Of course, this does not (yet) concern blackcurrants. But the whole project aims at continuously improving the groupwide sourcing system.

Of course, this does not (yet) concern blackcurrants. But the whole project aims at continuously improving the groupwide sourcing system.

“Of course, Austria Juice also wants to have as much contracted production as possible. It allows us to guarantee the quality of our raw material, have stable prices and guaranteed quantity of fruits. Stability in the market is as important for the growers as it is for the processors.” adds Franz Ennser, CEO of Austria Juice. (read more on the company’s policy in the blackcurrant sector)

Reporting, Standards, platforms and certification

Compliance with laws and regulations is a cornerstone of the sustainable business in general. It also applies to Austria Juice. The processor has a group-wide compliance management system, which governs several topics. These include assistance with compliance issues.Austria Juice is, for example, member of the “Supplier Ethical Exchange Database” (SEDEX). Sedex is the largest collaborative platform for managing ethical supply chain data. Its members can share and manage information related to Labour Standards, Health & Safety, the Environment and Business Ethics.Furthermore, the international supplier evaluation platform Ecovadis assesses Austria Juice’s sustainability performance annually.Austria Juice is also member of the Sustainable Juice Covenant (SJC). As such, they are committed to making the sourcing, production, and trading of fruit and vegetable juices, purees, and concentrates 100% sustainable by 2030.

Product responsibility & innovation

The ultimate goal of the Austria Juice’s quality policy is to produce foods and beverages that are safe for consumer needs. But that is not all: quality leadership in the processing of agricultural raw materials is outlined as the ultimate goal. In order to meet this goal, the company established a certified quality management system. Numerous other certifications for food safety, product protection and energy efficiency supplement it.

Sustainability in energy and water management

“Austria Juice focuses on continuously improving its production facilities in terms of managing energy and reducing fresh water usage. We also target the reduction of waste and greenhouse gas emissions. Recently, we have invested in high efficiency boilerhouses. We have also established close collaboration with local biogas facilities, as we supply them with raw materials for renewable energy. Finally, we work on the reduction of fresh water water usage by constantly investing in process and technology.”

Before we talk about new challenges related to climate change, let’s have a look at the basics. Blackcurrants grow naturally in temperate climate. Their home is the region spanning between the tropics and the polar regions of Earth. They need distinct seasonal changes: warm summers and cold winters.

Before we talk about new challenges related to climate change, let’s have a look at the basics. Blackcurrants grow naturally in temperate climate. Their home is the region spanning between the tropics and the polar regions of Earth. They need distinct seasonal changes: warm summers and cold winters. The blackcurrant is not very demanding in terms of soil, sunshine and water. The natural conditions in its climatic zone are perfect, and the plants don’t require special layouts. They just grow – and give a good yield. Mechanical harvesting has developped in the 1980ies and made it easy for growers to harvest huge quantities of blackcurrants within a few days and with very few workers. The juice concentrate business paid good prices for blackcurrants for several years, and growers could earn a good living. It sounds like paradise.Then came overproduction, and what had been a dream world for many has become a nightmare within a few years. The blackcurrant growing surface kept growing, and resulted in overproduction, especially in Poland. This naturally led to lower prices.Today, the situation starts getting back to normal, as the production in Poland decreases little by little and corresponds more to what the market demands.

The blackcurrant is not very demanding in terms of soil, sunshine and water. The natural conditions in its climatic zone are perfect, and the plants don’t require special layouts. They just grow – and give a good yield. Mechanical harvesting has developped in the 1980ies and made it easy for growers to harvest huge quantities of blackcurrants within a few days and with very few workers. The juice concentrate business paid good prices for blackcurrants for several years, and growers could earn a good living. It sounds like paradise.Then came overproduction, and what had been a dream world for many has become a nightmare within a few years. The blackcurrant growing surface kept growing, and resulted in overproduction, especially in Poland. This naturally led to lower prices.Today, the situation starts getting back to normal, as the production in Poland decreases little by little and corresponds more to what the market demands.

Over the past years, we have regular reports from growers who complain that part of their harvest – if not all – is destroyed within a single night of frost in April / May.

Over the past years, we have regular reports from growers who complain that part of their harvest – if not all – is destroyed within a single night of frost in April / May.

The blackcurrant fields of Burgundy are almost the farthest South in Europe. And although the variety may play a major role in the problem with scales, they now appear also further North. Is there a relation with the climate change? We cannot foresee this yet, but it is a possibility. Together with changing conditions as far as temperatures and humidity are concerned, deseases will develop or decrease accordingly.

The blackcurrant fields of Burgundy are almost the farthest South in Europe. And although the variety may play a major role in the problem with scales, they now appear also further North. Is there a relation with the climate change? We cannot foresee this yet, but it is a possibility. Together with changing conditions as far as temperatures and humidity are concerned, deseases will develop or decrease accordingly.

Nevertheless, there is still a long way to go. But unfortunately, we are running out of time. It is time to act, more than to think. Because one thing is sure: we will first see and suffer from the effects of climate change in agriculture.

Nevertheless, there is still a long way to go. But unfortunately, we are running out of time. It is time to act, more than to think. Because one thing is sure: we will first see and suffer from the effects of climate change in agriculture. Previous research from the Institute has highlighted the threat that climate change poses to blackcurrant farming. As we all know, the plants need a period of sustained cold weather in the winter. Without the winter chill, they yield less fruit and have a shorter lifespan.The UK’s 10 hottest years on record have all occurred since 2002. Winters in the UK and all over the world are getting gradually warmer. This is one of the challenges that all blackcurrant growers will have to deal with.

Previous research from the Institute has highlighted the threat that climate change poses to blackcurrant farming. As we all know, the plants need a period of sustained cold weather in the winter. Without the winter chill, they yield less fruit and have a shorter lifespan.The UK’s 10 hottest years on record have all occurred since 2002. Winters in the UK and all over the world are getting gradually warmer. This is one of the challenges that all blackcurrant growers will have to deal with.

“Together with

“Together with